Non-combustible façade panel: ALPOLIC NC/A1

Choosing the right building material is crucial for the safety of buildings. Materials are categorised according to their flammability in Euroclasses from F (inflammable) to A1 (non-combustible). Especially in safety-critical areas such as the façades of high-rise buildings or public buildings, the choice of an A1-classified material is crucial.

As the world's first composite material with an A1 classification, ALPOLIC™ NC/A1 aluminium composite panel offers unparalleled fire protection performance that meets the highest safety requirements:

✔ Maximum fire protection:

Tested in extensive large-scale fire tests and SBI tests by certified institutes.

✔ Reduced fire residues:

The debris of ALPOLIC™ NC/A1 is considerably lower and also significantly lighter than comparable façade claddings made of solid aluminium.

✔ Lowest calorific value (PCS value):

ALPOLIC™ NC/A1 has by far the lowest PCS value (8 MJ/m2) compared to other façade materials.

Experience the difference - now in the video!

Watch our video to see how ALPOLIC™ NC/A1 proves its outstanding fire protection performance under extreme conditions. In addition, impressive large-scale fire tests, direct comparison tests with solid aluminium and discover further advantages of our innovative composite material.

Boost your performance with ALPOLIC™: discover the benefits!

Product Performance

The special composition of the core material in combination with our unique fusion process makes ALPOLICTM composite panels so superior.

Processing Performance

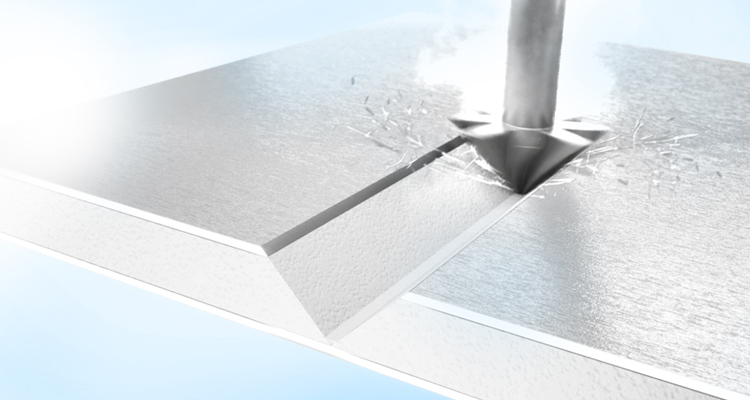

Significantly more precise routing and cutting with clean cut edges. Only one person required for edging even large panel formats.

Installation Performance

With ALPOLICTM you save up to 50 % on the substructure and installation time without compromising the stability of the façade!

Express Performance

Our high-quality composite panels are now available immediately from stock in selected formats and colours.

Design Performance

With a portfolio of over 200 colours, decors and surface designs, ALPOLICTM is an almost inexhaustible source of inspiration for architects and fabricators.

Sustainability Performance

Only ALPOLICTM offers you the non-combustible aluminium composite panel ALPOLIC™ NC/A1 with the highest fire protection class A1.