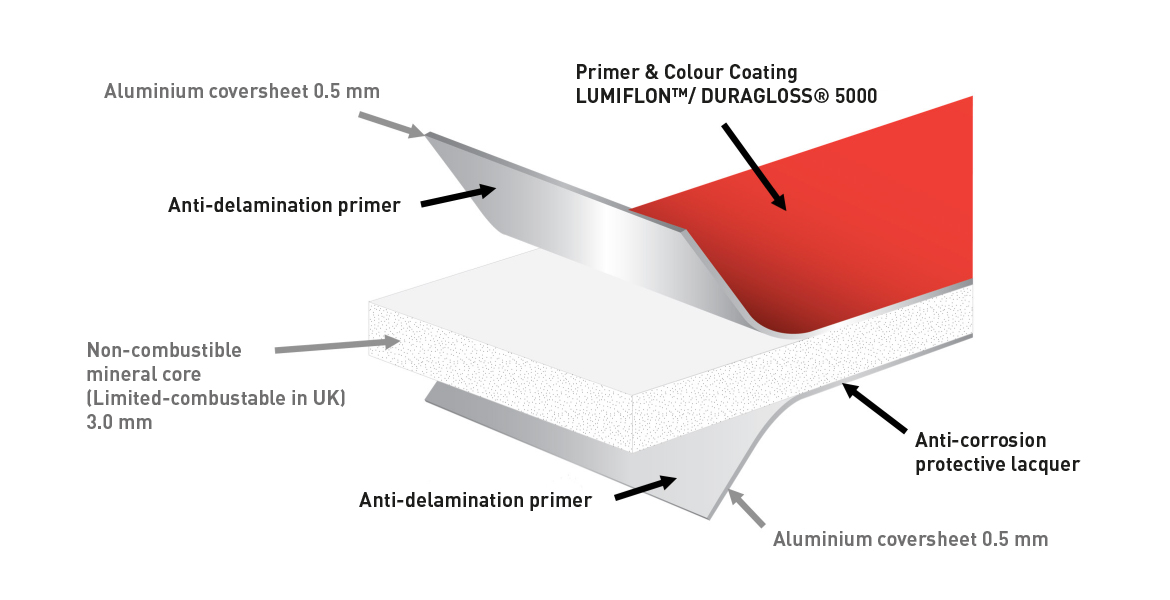

| Dimensions | Standard | Unit | Value | |

| Total Thickness | - | mm | 4 (± 0.2 mm) | |

| Cover sheet thickness | - | mm | 0.5 | |

| Core thickness | - | mm | 3 | |

| Width | - | mm | 1,000 / 1,250 / 1,500 / 1,750 / 2,015 (± 2 mm) | |

| Length | - | mm | max. 7,300 (± 1.0mm / m) | |

| Technological Value | ||||

| Weigth | - | kg/m2 | 8.4 | |

| Tensile strength | DIN EN 1396 | N/mm2 | 150 | |

| 0.2% proof stress | ASTM E8 | N/mm2 | 130 | |

| Elongation | ASTM E8 | % | 3 | |

| Flexural elasticity, E | ASTM D393 | kN/mm2 | 38.5 | |

| Deflection temperature | ISO 75-2 | °C | 110 | |

| Thermal expansion | ASTM D696 | 10-6 /°C | 19 | |

| Heat potential of the core | – | MJ /kg | < 3 | |

| Surface | ||||

| Coil-Coating | - | - | LUMIFLONTM Fluorpolymer coating (FEVE) | HDP (High Durable Polymer) |

| Aluminium alloy | - | - | 3105 H44 and 3005 H44 | |

| Gloss (measured at 60°) | EN 13523-2 | % | 15-80 | High gloss, silk matt, |

| Pencil hardness | EN 13523-4 | - | H | >HB |

| Resistance to rapid deformation | EN 13523-4 | - | Rear impact deepening at 7.5Nm/mm: No cracks | |

| Resistance to immersion in water | EN 13523-9 | - | After 500 hours: No influence | |

| Chalking resistance | EN 13523-14 | - | Chalking out after 1,000 Q-UV test hours (= 500 hours UV-B): ≤ 10% | |

International fire classifications

| Country | Test Standard | Results & Classification |

| EU(applicable in Europe, Switzerland and Turkey) | EN 13823, EN ISO 1716, EN 13501-1 | Class A2 - s1, d0 |

| Switzerland | VKF | RF 1 |

| France | - | M 0 |

Great Britain | BS 476 Part 6 & 7, BS 8414-1, BS 8414-2 | BR 135 |

| Russia | GOST 30244-94 method II, SNIP 21-01-97*,TsNIISK Natural Fire Test | Class G1 "Falme-retardant materials which do not burn without a source of fire." |

| USA | NFPA (ISAM Test) | passed |

Large fire testing

| Country | Test & Certificate |

| France | LEPIR2, IT249 APL n° EFR-22-002172 & n° EFR-21-002195 |

With more than 200 different colours and surface designs in various degrees of gloss, your creativity knows no bounds. Let yourself be inspired!

Design Decore

Prismatic

Metallic

Uni colours

ALPOLIC™: Technical Datasheet ALPOLIC™ A2