Especially in cities and conurbations, the trend is towards high-density construction - high-rise construction is on the rise. As building heights increase, so do the requirements for safety and fire protection. For good reason: because a faulty fire protection concept can not only cause high material damage in an emergency, but also endanger human lives. This is proven by the repeated occurrence of high-rise building fires with devastating consequences, which are also due to the use of combustible building materials. Particular attention is paid to façade cladding - because this has repeatedly been identified as a possible "fire accelerator". For building owners, planners and architects, it is therefore more important than ever to pay attention to the fire safety of the materials used when planning buildings.

For the granting of a building permission, a corresponding fire protection concept and fire protection certificate must be provided for each building. Particularly for high-rise buildings and high-risk buildings (hospitals, hotels, retirement homes, etc.), strict legal regulations apply in this respect - both for building planning and the selection of materials. According to the legislator, only non-combustible building materials must be used. This also applies to façade materials, as they are an essential part of the building envelope and thus make a significant contribution to the fire safety of a building. Since architects and planners bear a decisive responsibility in the planning and execution of the fire protection measures required by law and building regulations, the choice of a suitable façade material is therefore of the utmost importance.

ALPOLICTM A1 - first composite material worldwide with A1 classification

Against this background, the Mitsubishi Chemical Corporation has developed ALPOLICTM A1, the world's first aluminium composite material (ACM) classified according to the European Fire Protection standard DIN EN 13501-1, Euroclass A1. This means that the material is non-combustible and does not develop any smoke in the event of fire. In addition, the heat potential of the core material is max. 1 MJ/kg. ALPOLICTM A1 is therefore particularly recommended for applications in the building industry or in architecture where there are increased requirements for fire protection.

ALPOLICTM A1 - much more than safe

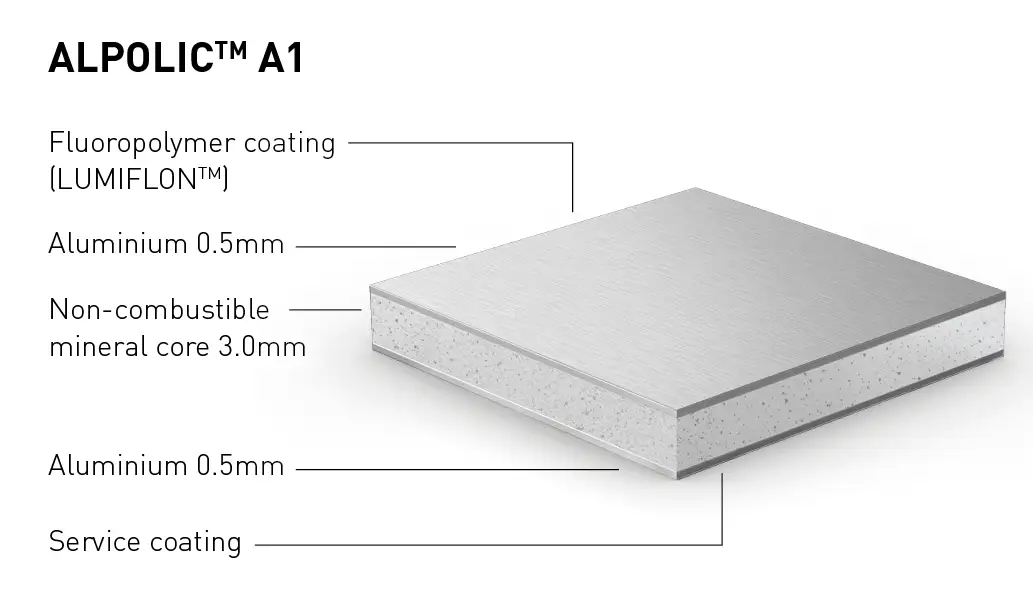

ALPOLICTM A1 is a three-layer composite material (ACM) produced by laminating two aluminium sheets to both sides of a core material. Thanks to its excellent surface finish, flatness, colour variety and very good processing properties, ALPOLICTM offers almost unlimited design possibilities in both existing and new buildings.

ALPOLICTM also convinces in terms of sustainability with a positive eco-balance - an important selection criterion even in the early planning phase.

The composite panels are produced according to the strictest environmental regulations and are almost 100 percent recyclable. Even the waste generated in the production process is collected and returned to the material cycle.

Text volume:

392 Words, 3.189 Characters (including spaces)

Reprint free of charge. We would be pleased to receive a copy.

Press contact:

teampenta GmbH & Co. KG

Liane Hötger

Seibertzweg 2

44141 Dortmund

Tel.: +49 231 556952-64