Our product variants - the right solution for every project!

Our aluminium composite panels consist of two aluminium cover sheets that are pre-finished with high-quality lacquers in a continuous coil coating process and then applied to a mineral core in a fusion bonding process.

The front of the composite panels is coated with LUMIFLONTM - based on a transparent fluoropolymer resin (FEVE) - or with High Durable Polymer (HDP). The high-quality colour coatings ensure that the surfaces of our products are protected against weathering and corrosion for decades and are extremely colourfast and dirt-resistant. Depending on your project requirements, you can choose between the following variants:

Discover more advantages!

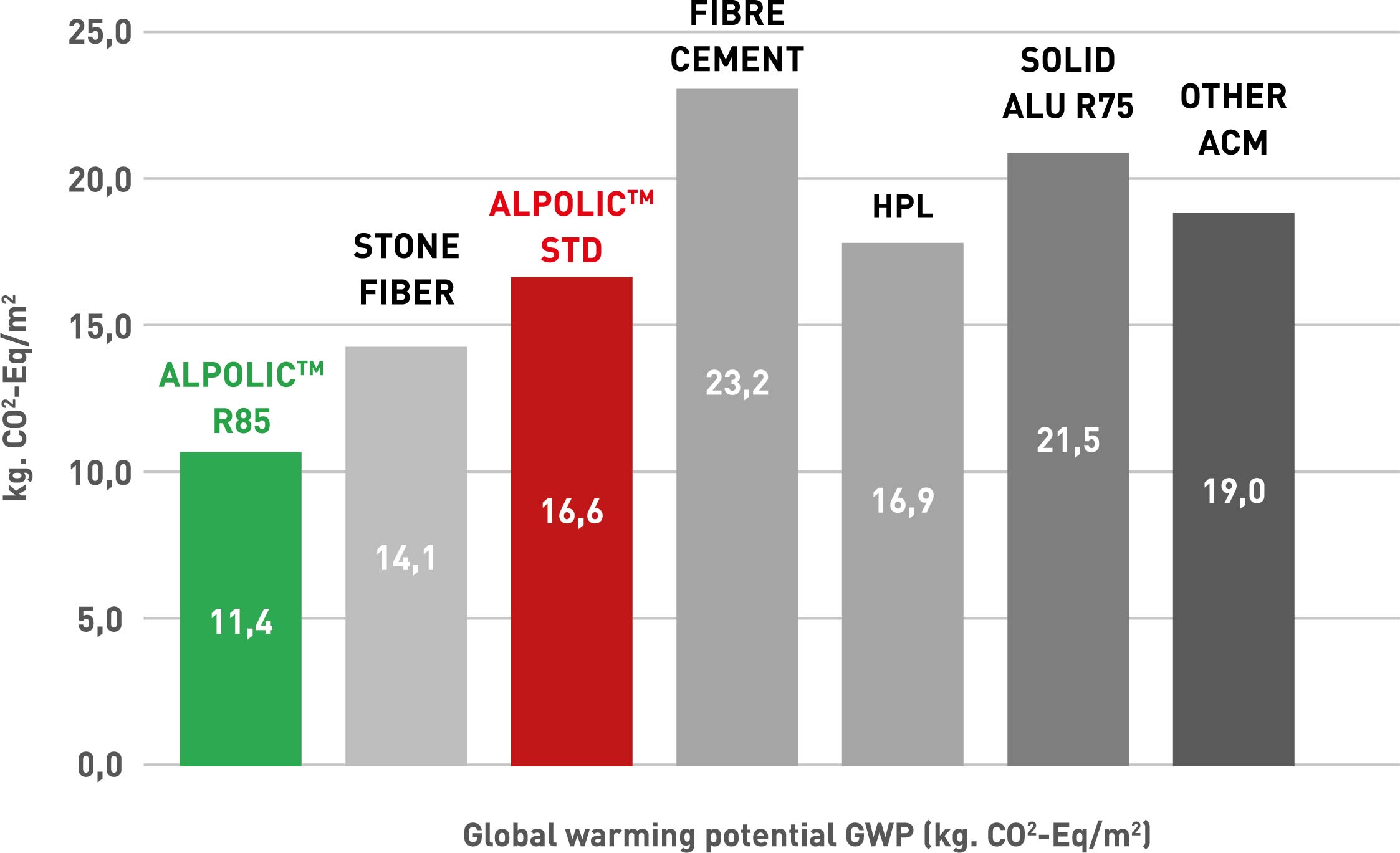

Documented climate-friendly - EPD certified

Our standard composite panels with 50% recycled content already achieve a low Global Warming Potential (GWP) of 16.6 kg CO₂-eq/m².

With ALPOLICTM R85 - consisting of 85% recycled aluminium - we have reduced this value again by almost 40% to just 11.4 kg CO₂-eq/m²!

The result:

- 60% lower CO₂ footprint compared to conventional ACM panels without recycled content

- EPD-certified (Environmental Product Declaration) - for maximum planning security

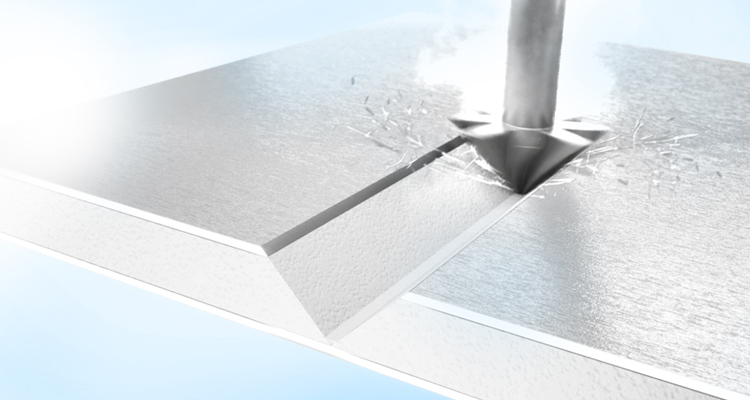

Processing: Comfortable. Precise. Clean.

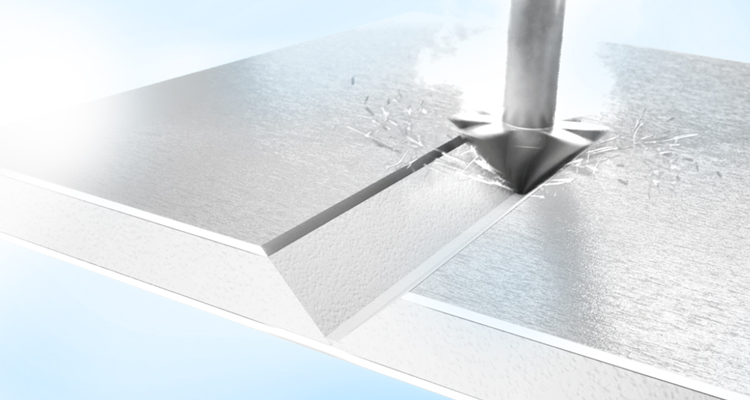

ALPOLIC™ aluminium composite panels can be cut, milled, edged or drilled effortlessly using standard tools for metal and aluminium processing. The combination of a very stable yet flexible sheet structure enables maximum precision - both for simple cuts and complex geometries. Thanks to their special design and high-quality surface coating, they produce smooth, clean edges during machining. In most cases, no post-processing is required - this saves time, reduces material losses and ensures particularly efficient processing on the construction site or in the workshop.

Design diversity: Versatile. Durable.

In architecture, colours are far more than just decoration - they shape identity, lend character and create an emotional impact. With over 200 colours and decors, ALPOLIC™ offers maximum creative freedom: from elegant solid colours and brilliant metallic and glitter effects to prismatic highlights and nature-inspired decors - available in various gloss levels. This makes every façade unique.