"Sustainability is firmly anchored at ALPOLIC – we reduce resource consumption and emissions and offer sustainable solutions for the construction industry with durable, recyclable products."

Sven Stötzer, General Manager ALPOLICTM EMEA

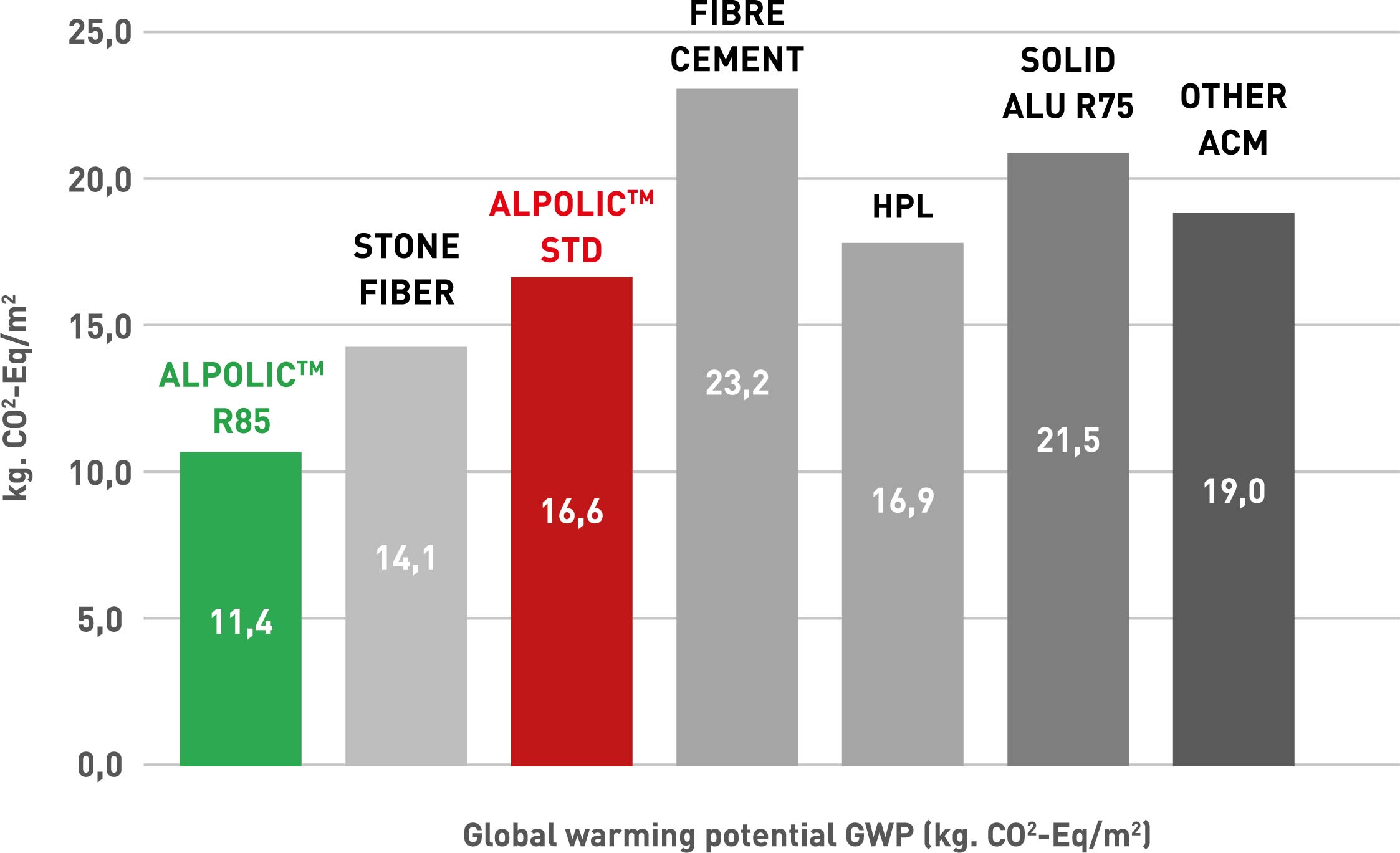

A comparison with EPDs from other European manufacturers shows:

- Even our standard products and R75 variants cause significantly less CO₂ emissions during the manufacturing phase.

- With the new ALPOLICTM R85 product variant, we achieve a peak value of only 11.4 kg CO₂ equivalent per m² thanks to 85% recycled aluminium in the cover sheets.

- This means over 40% less CO₂ emissions compared to comparable façade materials.

This makes ALPOLICTM one of the leading ecological façade materials on the market – independently tested, certified and ideal for any project that values sustainability.