Fire safety is a key aspect of building planning and has a significant impact on the choice of suitable construction materials. Depending on the building category – especially in high-risk buildings – strict legal requirements apply. In light of recent large-scale fire incidents, the importance of proper fire protection measures has further increased.

At the European level, the fire classification of construction products is regulated by DIN EN 13501-1. This standardized system assesses not only the combustibility of a product but also its smoke development and the production of burning droplets or particles.

The seven fire classes (Euroclasses) at a Glance:

The DIN EN 13501-1 standard defines seven fire classes, also known as Euroclasses, ranging from A1 (non-combustible) to F (easily flammable). In addition to basic fire behaviour, the classification also considers smoke development and burning or falling particles. This gives insight into how much a material contributes to the outbreak and spread of fire.

- A1 & A2 – non-combustible, no contribution to fire

- B – limited combustibility, very low contribution

- C – limited combustibility, low contribution

- D – normally combustible, acceptable contribution

- E – normally combustible, limited fire behaviour

- F – easily flammable, no performance determined

Additional Classifications: Smoke and Burning Droplets

Alongside the main fire class, materials are also classified by two additional criteria:

- Smoke Production (s-classifiication)

Smoke emission is assessed using the SBI (Single Burning Item) test and divided into three levels: - s1: low smoke production – minimal impact on visibility and air

- s2: medium smoke production – moderate exposure

- s3: high smoke production or not tested – potentially hazardous

- Burning Droplets (d-classification)

The "d" rating refers to the presence of flaming droplets or particles during the first ten minutes of fire exposure:- d0: no flamin droplets

- d1: limited flaming droplets (no flames lasting longer than 10 seconds)

- d2: : high flaming droplets or not assessed

Testing methods for determining fire classes

The classification of building materials is based on standardised test methods. The following main properties are analysed: Flammability, smoke development, burning droplets. The limit values of the Euroclasses are essentially based on SBI tests (test of a single burning object) or the more extensive ‘Room Corner Tests’ (ISO 9705). Based on the results, the tested building materials are categorised into the corresponding Euroclasses. The boundaries between the individual classes are determined by the time period until the ‘flashover’.

Testing methods at a glance:

- SBI-Test (Single Burning Item, EN 13823):

The SBI test is used to assess the fire behaviour of a construction product and simulates the start of a fire. The classification (Euroclass) is based on the various parameters tested - for example flame spread, flammability, amount of heat, smoke and toxic gases. Whether a product melts, drips or chars is also taken into account.

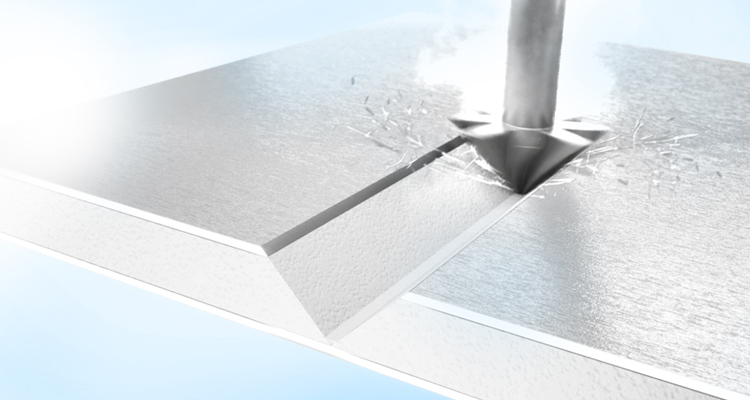

- Flammability test (EN ISO 11925-2):

In this very simple test set-up, a small flame is used to determine whether a product can easily ignite and whether the fire expands quickly. This method is used to categorise classes B, C, D and E.

- Non-combustibility test (EN ISO 1182):

This test is used to identify A1 and A2 classified products - i.e. those that do not or do not significantly contribute to a fire. A material sample is placed in an oven heated to approx. 750 °C for a maximum of 60 minutes. The classification depends on the temperature change, mass loss and duration of the sustained ignition.

- Calorific value test (EN ISO 1716):

This test to determine the specific calorific value determines the potential maximum total heat output of a product when fully combusted. A powdered test specimen is ignited under pressurised oxygen in a closed steel cylinder surrounded by water. To determine the calorific potential (PCS), the temperature rise of the water is measured. If the value remains below max. 2 MJ/kg, the material is categorised as A1.